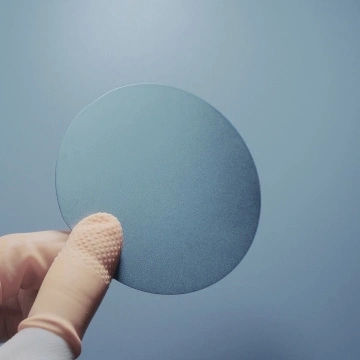

Regarding coated silicon Glass Wafers selection: Coated wafers are a subset of Silicon Wafers in which one or both surfaces are coated with additional materials. Among this Thin Si Wafers produced in Zoolied, they are characterized by COATING—the material coated on the wafer; and the thickness of the coating—the thickness of the coating, usually µm, nm, or Å.

Oxide wafer

A typical coating required is an oxide coating. This can be a thermal oxide coating (ATOx), which always covers both sides of the wafer. ATOx stands for atmospheric thermal oxide. Other oxide coating methods include: Dry Oxide-produces a thinner oxide layer, but has a higher uniformity film. PECVD oxide-produces a coating on a single side of the wafer.

Nitride wafer

The second typical coating required is a nitride coating. Silicon nitride (SiN) provides different mechanical and chemical properties for the oxide layer. Nitride can be deposited by PECVD, LPCVD or low stress LPCVD. These variants are changes in the deposition method and change the final physical and mechanical properties of the film.

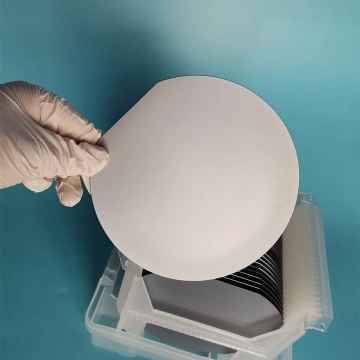

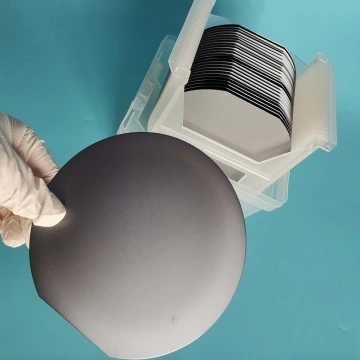

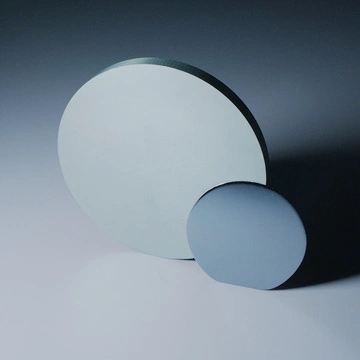

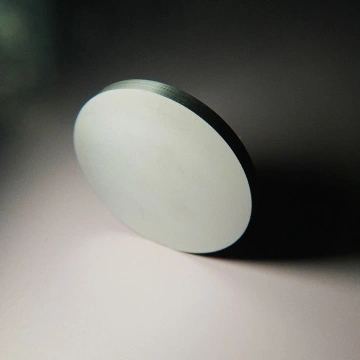

Zoolied offers a variety of optical glass wafers, such as Dummy Silicon Wafers, Jgs1 Wafers, and K9 Wafers, and Bk7 Wafers. ZOOLIED provides multiple anti-reflection coating options and also provides uncoated optical glass wafers. Looking for ideal optical si wafers and Ge Wafers Manufacturer & supplier? We have a wide selection at great prices to help you get creative. All the optical glass wafers are quality guaranteed. Zoolied is China Origin Factory of optical Wafers. If you have any question, please feel free to contact us.

Note: Please pay attention to your email at any time after inquiring, we will send you the quotation by email.

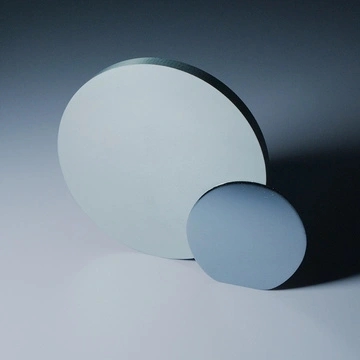

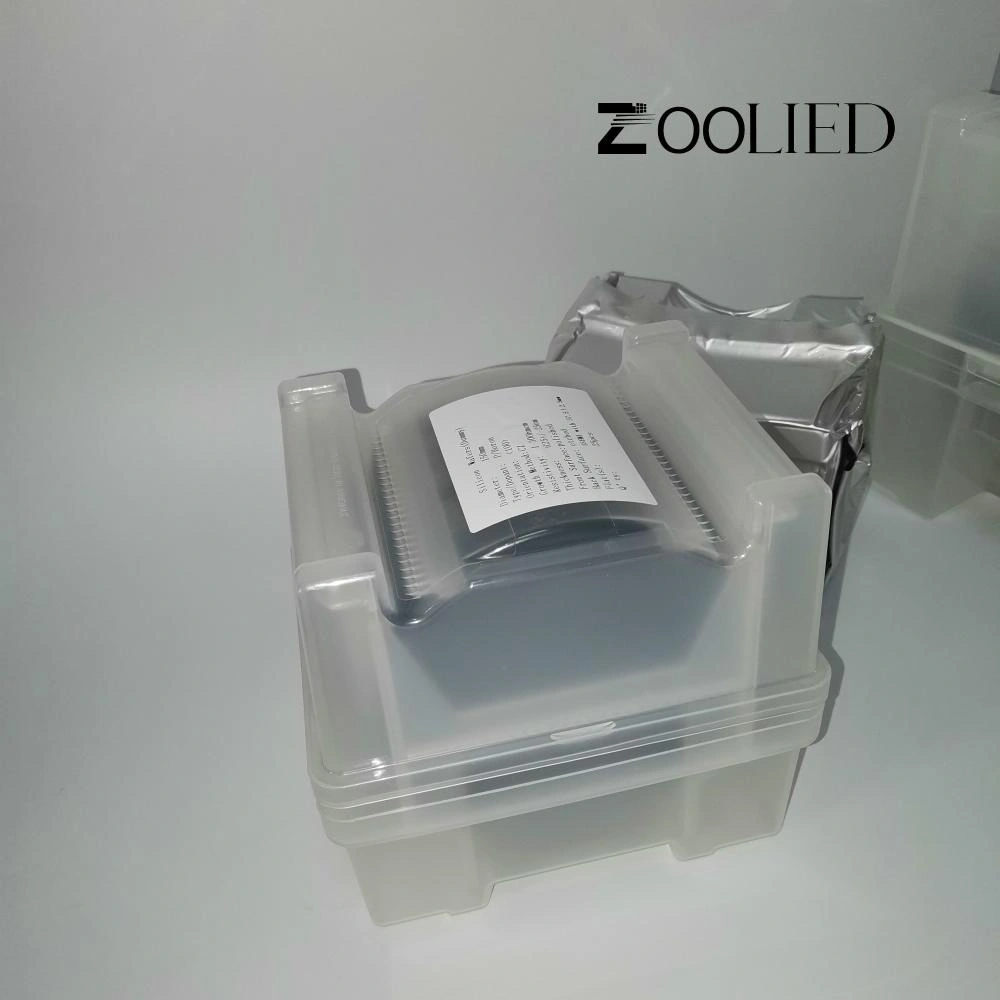

| Zoolied Standard Silicon Wafer | |||||||

| Diameter | 2" | 3" | 4" | 5" | 6" | 8" | 12" |

| Grade | Prime/ Test/ Dummy | ||||||

| Growth Method | CZ/FZ | ||||||

| Orientation | < 100 > , < 111 > , < 110 > | ||||||

| Type/Dopant | P/Boron , N /Phos, N /As, N /Sb | ||||||

| Thickness (um) | 279 | 380 | 525 | 625 | 675 | 725 | 775 |

| Thickness Tolerance | Standard ± 25μm | ||||||

| Resistivity | 0.001 - 10,000ohm-cm | ||||||

| Surface Finished | DSP,SSP | ||||||

| TTV (um) | Standard < 10 um | ||||||

| Bow/Warp (um) | Standard <40 um | ||||||

| Particle | Specified by customer | ||||||