Zoolied Inc.一Right-Angle Prisms: Design, Applications, and Optical Properties

2025-6-26

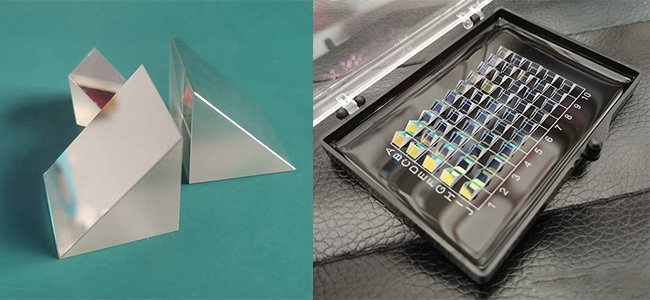

A right-angle prism is a common optical component with a 90-degree triangular cross-section, typically made from high-quality glass or other transparent materials. These prisms are widely used in imaging, laser systems, and beam steering applications due to their ability to reflect and deviate light efficiently. This article explores the optical principles, manufacturing considerations, and key applications of right-angle prisms.

Optical Principles

Right-angle prisms are designed with two perpendicular faces (legs) and a hypotenuse face. When light enters one of the perpendicular faces, it undergoes total internal reflection (TIR) at the hypotenuse, redirecting the beam by 90°. Alternatively, if the hypotenuse is coated with a reflective material, the prism can function as a mirror, even for non-TIR conditions.

Key Characteristics:

Beam Deviation: Typically 90°, but can vary based on orientation.

Surface Quality: High-precision prisms have λ/4 or better surface flatness.

Material Options: BK7, fused silica or specialty glasses for UV/IR applications.

Manufacturing and Tolerances

Precision is critical in right-angle prism manufacturing. Key tolerances include:

Angle Accuracy: ±3 arcminutes or better for high-end applications.

Surface Flatness: λ/4 or λ/10 for laser systems.

Coating Options: Anti-reflective (AR), metallic, or dielectric coatings for enhanced performance.

Applications

Beam Steering & Folding: Redirects light paths in optical systems without significant power loss.

Imaging Systems: Used in periscopes, binoculars, and telescopes for compact optical routing.

Laser Systems: Provides stable beam deflection in laser cavities and alignment setups.

Retroreflection: Acts as a corner reflector when light enters the hypotenuse, sending it back parallel to the incident beam.

Right-angle prisms are versatile optical components essential for beam manipulation, imaging, and laser applications. Their efficiency, compact design, and adaptability make them indispensable in both industrial and scientific optics. Advances in coating technology and precision manufacturing continue to expand their utility in emerging photonic systems.