How to choose the best optical solution for you

2025-2-25

In today's modern world of rapid technological advancement, optical components have become indispensable core components for many industries. As a company specializing in the production of optical components such as lenses, prisms, windows, filters, etc., we understand the technical details and application scenarios behind each optical component. In this blog, we'll explore how to choose the optics that best suit your needs and share some of the latest trends in optical manufacturing.

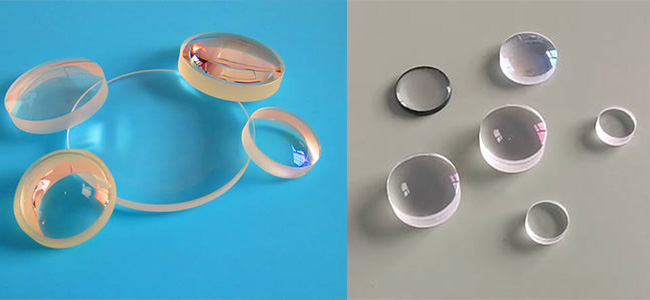

1. Lens: the heart of an optical system

Lenses are one of the most common components in optical systems and are widely used in imaging, focusing and beam shaping. When choosing a lens, the following key factors need to be considered:

Material: Different application scenarios require different materials. For example, UV applications typically require fused silica or calcium fluoride, while visible light applications can use optical glass such as BK7 or SF11.

Radius of curvature and focal length: These parameters determine the optical performance of the lens and directly affect the quality of the image and the focusing of the beam.

Coating: Anti-reflective coating reduces light loss and improves light transmission, especially important in multi-lens systems.

2. Prisms: optical path control and beam splitting

Prisms are mainly used in optical systems for light path steering, beam splitting and dispersion. Common types of prisms include right-angle prisms, pentagonal prisms and beam-splitting prisms. When choosing a prism, you need to consider:

Angular accuracy: The angular accuracy of a prism directly affects the accuracy of the light path, especially in laser and precision measurement applications.

Material selection: Similar to lenses, the choice of material for prisms needs to be determined by the spectral range of the application scenario.

Surface quality: Prisms with high surface quality reduce scattering and light loss, ensuring efficient operation of the optical system.

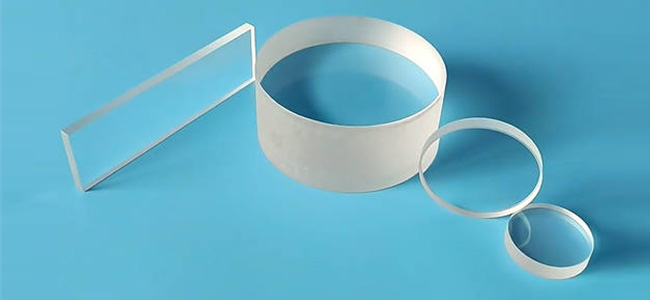

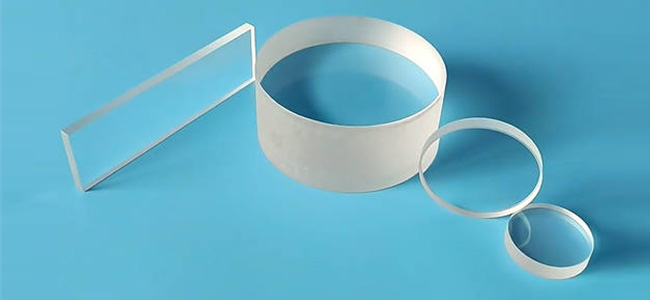

3. Optical windows: protection and light transmission

Optical windows are primarily used to protect sensitive optics or detectors while allowing light to pass through. When selecting an optical window, care needs to be taken:

Optical properties of the material: Window materials should have high light transmission and low absorption, especially in the ultraviolet, visible or infrared spectral range.

Mechanical strength: Windows are usually subject to a certain amount of mechanical stress, so the hardness and impact resistance of the material are also important considerations.

Environmental adaptability: If the window needs to be used in extreme environments (e.g. high temperature, high pressure or corrosive environments), the choice of material and coating technology will become particularly important.

Prisms are mainly used in optical systems for light path steering, beam splitting and dispersion. Common types of prisms include right-angle prisms, pentagonal prisms and beam-splitting prisms. When choosing a prism, you need to consider:

Angular accuracy: The angular accuracy of a prism directly affects the accuracy of the light path, especially in laser and precision measurement applications.

Material selection: Similar to lenses, the choice of material for prisms needs to be determined by the spectral range of the application scenario.

Surface quality: Prisms with high surface quality reduce scattering and light loss, ensuring efficient operation of the optical system.

3. Optical windows: protection and light transmission

Optical windows are primarily used to protect sensitive optics or detectors while allowing light to pass through. When selecting an optical window, care needs to be taken:

Optical properties of the material: Window materials should have high light transmission and low absorption, especially in the ultraviolet, visible or infrared spectral range.

Mechanical strength: Windows are usually subject to a certain amount of mechanical stress, so the hardness and impact resistance of the material are also important considerations.

Environmental adaptability: If the window needs to be used in extreme environments (e.g. high temperature, high pressure or corrosive environments), the choice of material and coating technology will become particularly important.

4. Filters: precise control of the spectrum

Filters are used to selectively transmit or block specific wavelengths of light and are used in a wide range of applications including spectral analysis, fluorescence imaging and laser systems. When selecting filters, it is important to consider:

Spectral characteristics: The transmittance and cutoff wavelength of the filter must match your application requirements.

Bandwidth and slope: Narrow band filters are suitable for precise spectral selection, while broad band filters are suitable for a wider spectral range.

Durability: Filters are often required to operate with high energy lasers or in harsh environments, so their durability and thermal stability are critical.

5. Recent trends in optical manufacturing

As technology advances, manufacturing processes for optical components are being revolutionized. Here are some of the latest trends:

Ultra-precision machining: With advanced CNC machine tools and polishing techniques, the surface accuracy of optical components can reach the nanometer level, meeting the needs of high-precision optical systems.

Additive manufacturing (3D printing): 3D printing technology is gradually being applied to the manufacturing of optical components, especially in complex shapes and customized optical components show great potential.

Intelligent Coating Technology: More efficient optical performance, such as ultra-low reflectivity and high damage resistance threshold, can be realized through nanoscale coating technology.

The selection and manufacturing of optical components is a complex and sophisticated process that requires comprehensive consideration of materials, design, manufacturing processes and application scenarios. As a professional manufacturer of optical components, we are committed to providing high-quality, customized optical solutions for our customers. We provide you with professional technical support and consulting services.

Filters are used to selectively transmit or block specific wavelengths of light and are used in a wide range of applications including spectral analysis, fluorescence imaging and laser systems. When selecting filters, it is important to consider:

Spectral characteristics: The transmittance and cutoff wavelength of the filter must match your application requirements.

Bandwidth and slope: Narrow band filters are suitable for precise spectral selection, while broad band filters are suitable for a wider spectral range.

Durability: Filters are often required to operate with high energy lasers or in harsh environments, so their durability and thermal stability are critical.

5. Recent trends in optical manufacturing

As technology advances, manufacturing processes for optical components are being revolutionized. Here are some of the latest trends:

Ultra-precision machining: With advanced CNC machine tools and polishing techniques, the surface accuracy of optical components can reach the nanometer level, meeting the needs of high-precision optical systems.

Additive manufacturing (3D printing): 3D printing technology is gradually being applied to the manufacturing of optical components, especially in complex shapes and customized optical components show great potential.

Intelligent Coating Technology: More efficient optical performance, such as ultra-low reflectivity and high damage resistance threshold, can be realized through nanoscale coating technology.

The selection and manufacturing of optical components is a complex and sophisticated process that requires comprehensive consideration of materials, design, manufacturing processes and application scenarios. As a professional manufacturer of optical components, we are committed to providing high-quality, customized optical solutions for our customers. We provide you with professional technical support and consulting services.